What are the challenges in TPU sheet molding?

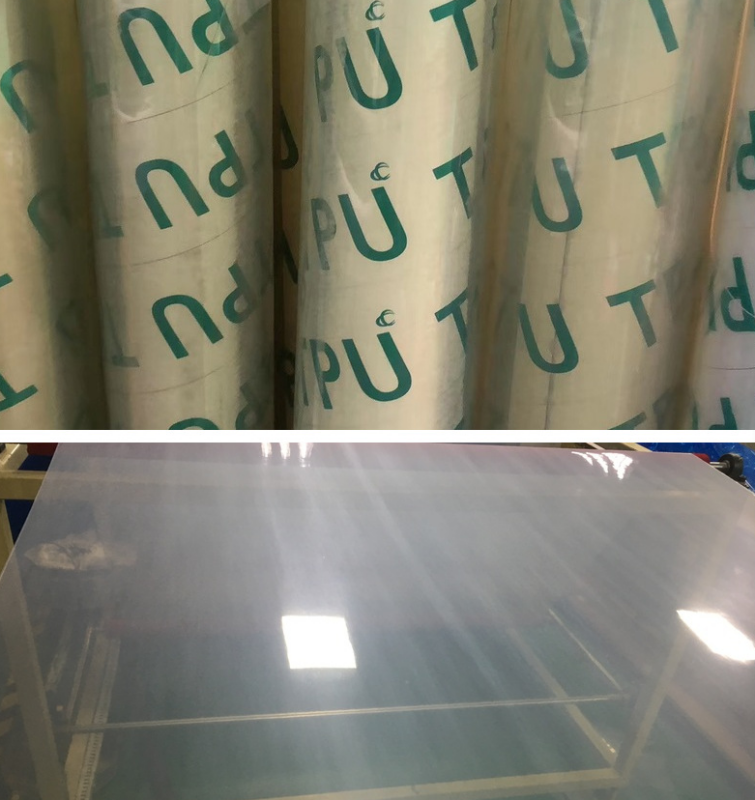

TPU sheet extruder machine offers a combination of elasticity, wear resistance, weather resistance, and environmental recyclability, making it widely used in medical, sports, and packaging applications. However, its wide hardness range (Shore A 60 to Shore D 80), sensitive melt viscosity, and susceptibility to hydrolysis and thermal degradation lead to three core challenges during the molding process: uniformity control, performance maintenance, and process stability. The specific challenges, their causes, and impacts are as follows:

1. Raw material pretreatment: Moisture control is challenging and directly impacts sheet quality.

TPU is a highly hygroscopic polymer. The urethane bonds in its molecular structure react easily with water. Exceeding the moisture content in the raw material can lead to a series of problems during the molding process. This is the primary pre-processing challenge for TPU sheet molding. Difficulties:

Rapid moisture absorption and difficulty in complete removal: TPU pellets exposed to air for just one hour can see their moisture content rise from 0.03% (the acceptable value) to over 0.1%. The absorption rate doubles in environments with humidity >60%. Furthermore, moisture easily penetrates the pellets, making it difficult to completely remove with conventional drying.

Narrow drying parameter window: If the drying temperature is too low (<80°C), moisture cannot fully evaporate. If the temperature is too high (>120°C), the TPU will soften and stick together prematurely, forming "lumpy agglomerations" and preventing proper feeding. If the drying time is too short (<4 hours), moisture will remain, while if it is too long (>8 hours), the TPU molecular chains will be slightly degraded, reducing its elasticity.

Direct Impact: After forming, bubbles and pinholes will appear on the surface of the sheet (caused by high-temperature vaporization of moisture), and "silver streaks" will form internally (due to uneven melt flow caused by moisture vapor). In severe cases, the sheet can delaminate and mechanical properties (such as tensile strength) can decrease by 15%-30%. II. TPU Sheet Extrusion Molding: Melt Flow and Temperature Control Are Core Technical Bottlenecks

The mainstream TPU sheet molding process is "single-screw/twin-screw extrusion followed by calendering." However, TPU melt exhibits significant non-Newtonian properties (viscosity is sensitive to temperature and shear rate), and the process compatibility of TPUs of varying hardness varies significantly. This makes it difficult to control uniformity and stability during extrusion, a key operational challenge for the equipment.

1. Sensitive melt viscosity can easily lead to uneven sheet thickness.

Causes of Difficulty:

TPU's melt flow rate (MFR) is extremely sensitive to temperature fluctuations: For every 10°C increase in temperature, the MFR can increase by 20%-30% (compared to only 5%-10% for standard PP). If the temperature of the extruder barrel fluctuates by ±3°C across sections, the melt viscosity will vary significantly, resulting in uneven die discharge speeds. Poor shear rate adaptability: Soft TPU (Shore A 60-80) has low melt viscosity. Excessively high screw speeds (>60 rpm) can easily cause melt fracture (rough and wrinkled material surfaces). Hard TPU (Shore D 60-80) has high melt viscosity, so low speeds (<30 rpm) can lead to insufficient plasticization, resulting in unmelted particles within the sheet.

Direct impact: Sheet thickness deviations exceed tolerances (acceptable deviation ≤ ±0.05mm, often exceeding ±0.1mm). Sink marks are common in areas where the material is too thick, while breakage is common in areas where the material is too thin. This makes the sheet unsuitable for high-precision applications such as medical films. 2. Extremely high temperature control precision is required to avoid thermal degradation and performance loss.

Difficulties:

TPU sheet extruder machine has a narrow thermal stability range: Most TPU processing temperatures range from only 200°C to 230°C. Temperatures above 240°C cause molecular chain breakage (decomposition of urethane bonds), releasing gases such as CO₂, resulting in "burned particles" (small black spots) in the sheet. Temperatures below 190°C result in insufficient melt fluidity, preventing the die cavity from filling, resulting in "shortage."

Barrel temperature gradient matching is difficult: TPU extrusion requires a strict "low-temperature feeding - medium-temperature plasticizing - high-temperature homogenizing" gradient (e.g., 180°C-190°C in the feeding section, 200°C-210°C in the plasticizing section, and 210°C-220°C in the homogenizing section). A gradient difference of less than 10°C results in uneven plasticization; a gradient difference greater than 30°C can easily lead to localized overheating and degradation. Direct Impacts: Sheet mechanical properties (such as elongation at break) deteriorate, the elastic recovery rate of soft TPU drops from 90% to below 70%, and the hardness of hard TPU decreases by 5-10 Shore degrees. The surface is prone to yellowing (caused by degradation products), affecting appearance.

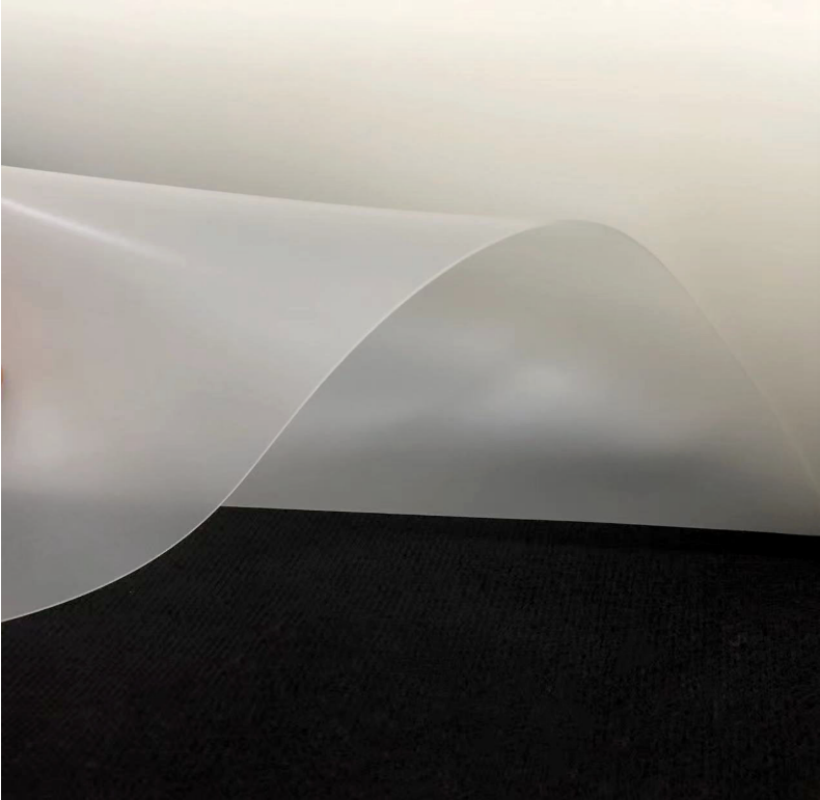

Third, TPU Sheet Calendering Equipment: It's Difficult to Balance Surface Quality and Dimensional Stability

After extrusion, TPU sheets must be shaped (controlling thickness and flatness) using a calendering roller system. However, TPU has a strong elastic memory effect (prone to rebound after cooling) and a high thermal shrinkage rate (typically 3%-5%, 2-3 times that of PP). This makes it difficult to simultaneously achieve both surface smoothness and dimensional accuracy during the calendering process, presenting a key post-molding challenge. Difficulty 1: Matching calender roll temperature and pressure.

If the calender roll temperature is too low (<60°C), the TPU melt cools too quickly on the roll surface and cannot fully adhere to the roll surface texture, resulting in a matte and hazy sheet surface.

If the pressure is too high (>15MPa), soft TPU is prone to "roller mark residue" (the roll surface texture is pressed too deeply), while hard TPU is prone to "stress cracking" at the edges. If the pressure is too low (<5MPa), bubbles within the melt cannot be eliminated, resulting in uneven sheet density. Difficulty 2: Conflict between Cooling and Dimensional Shrinkage. After the TPU sheet emerges from the calendering rollers (at a temperature of approximately 80°C to 100°C), it must be rapidly cooled to below 40°C by a "cooling roller assembly." However, cooling too quickly can lead to internal stress concentration in the sheet, making it prone to warping (e.g., upward bending of the edges) during subsequent storage. Cooling too slowly (>30 seconds) causes the TPU to continue shrinking, leading to increased dimensional deviation (e.g., 2% to 3% shrinkage in the longitudinal direction), making it unsuitable for subsequent cutting. IV. TPU Sheet Equipment Adaptability: Conventional Plastic Equipment Requires Targeted Modification

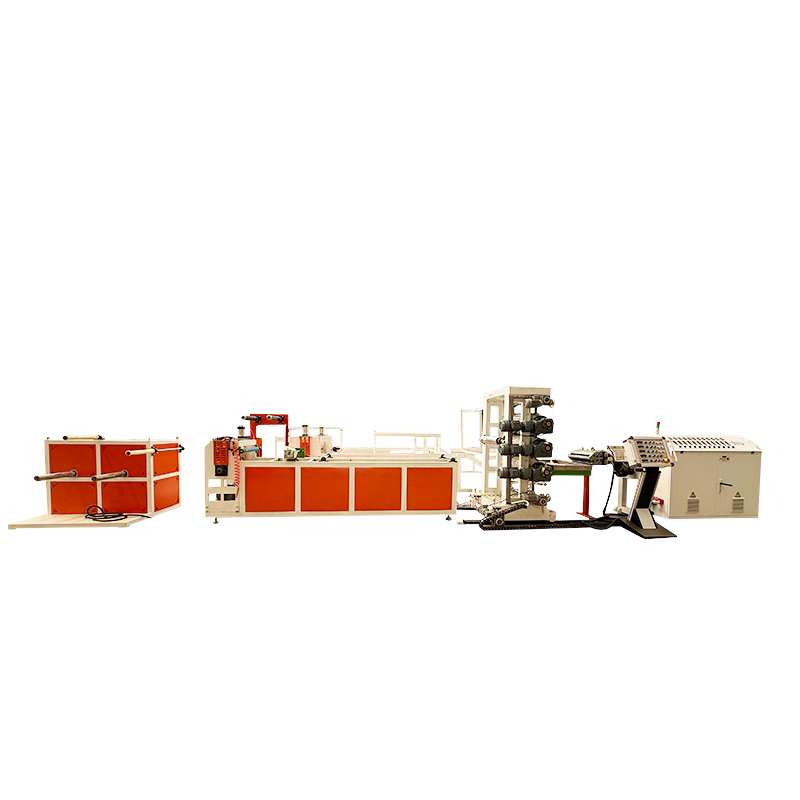

TPU sheet molding equipment cannot directly utilize conventional PP/PE extrusion equipment. Core components must be modified, otherwise the aforementioned difficulties will be exacerbated. This represents a hidden equipment-level difficulty:

Screw Structure Modification: Conventional screws (such as gradient screws) have low plasticizing efficiency for TPU and are prone to localized overheating. They should be replaced with "barrier screws" (with an additional mixing section) to improve plasticizing uniformity, but this modification is costly (approximately 50,000 to 100,000 yuan per unit).

Die Design Optimization: Conventional flat dies are prone to "melt retention" at the discharge port (TPU remains in the corners of the die for an extended period, leading to degradation). A "torpedo-head die" is required to reduce dead zones, and the die gap must be precisely adjustable (with an accuracy of ±0.01mm). Otherwise, uniformity cannot be achieved for thin TPU sheets (thickness <0.1mm).

Draw-off and Winding Control: TPU sheets are highly elastic, and the "constant tension control" of conventional draw-off machines is insufficient. It is prone to failure (tension fluctuations of ±5% will cause the sheet to stretch and deform), and needs to be replaced with a "servo motor traction system" with real-time adjustment of the tension sensor. When winding, a "surface winding method" must also be adopted (to avoid edge wrinkles caused by center winding), which significantly increases the equipment investment cost.